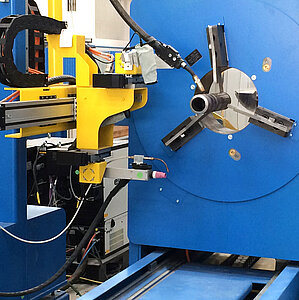

The TIG/MAG butt-welding machine is used to automatically weld pipes and fittings to each other.

This version of the machine is used for longer pieces of pipe, which are delivered to the machine on the automated transport system. The system drastically reduces overall manufacturing times, with improved seam quality.

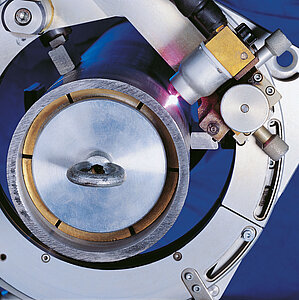

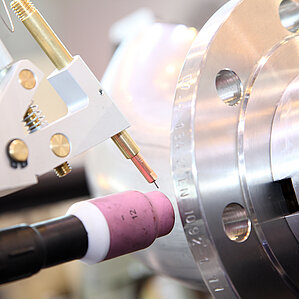

This machine uses an internal clamping system, which is inserted into the pipe and fitting to align them and allows for zero-gap welding without the need to tack-weld. Depending on the WPS the bevel will either be a V groove or a J groove, with a 2 mm root face.

The pipe is moved onto the infeed supports using transfer arms mounted on the buffer table. These arms deposit the pipe on the supports, which then move it into the chuck. Once the pipe is clamped in the chuck, the mandrel carriage moves forward to insert the mandrel with the inner clamping device into the pipe.

When the mandrel is in position, the operator uses a foot switch to engage the first clamp. Then the fitting is moved into position, either by hand or, for heavier fittings, by crane. The operator then engages the second clamp, holding the fitting in place, and initiates the welding process.

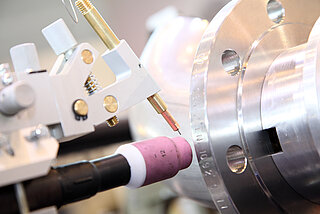

The root run of the joint will be welded with TIG. Afterwards additional layers of TIG or MAG will be welded, according to the established WPS.

- Pipe length 30 – 6000 mm

- Pipe diameter from 1“ – 16“

- Wall thickness from 1 – 20 mm