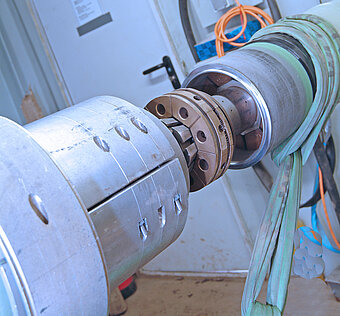

Internal clamping device with two pneumatic cylinders.

The clamping systems specially developed by Westfalen bring enormous benefits for pipe production. The numerous advantages facilitate prefabrication both in the pipe workshop and on construction sites. Savings of up to 60 % are possible.

- No stapling.

- Optimum pre-alignment of the pipe parts thanks to separate clamping (double cylinder).

- Gap-free pressing of the pipe parts to be welded together.

- Automatic centring of the pipe fittings.

- Minimises ovality tolerances.

- No post-treatment of the workpieces (tarnish-free root).

- Significantly reduced forming gas consumption (small forming gas chamber/no gas pre-flow time).

- Flexible use as a mobile construction site tool or in pipe production.

- Suitable for continuous use with water cooling.

- Clamping range from DN 25 - DN 400 mm.